Estun E21s Manual

Estun E21 Pdf User Manuals. View online or download Estun E21 Installation Manual. This manual and know operation requirements before using this device. Copy right is preserved by ESTUN. It is not allowed to add or delete part or all of the manual content without ESTUN’s consent. Do not use part or all of manual content for the third party’s design. E21S device provides complete software control and has no mechanical.

The stroke of slider and back gauge is adjusted automatically by double servo motors or transducer, and showed on CNC Mechanical torque or NC control panel. Slanting wedges can be chosen to install on the top dies which can be adjusted by hands or automatically. Light guards 6. Two micrometric backgauge finger-stops with lateral adjustment 7.

Steel mono-block construction 8. Polished chrome plated and ground cylinders 9. Long stroke and large open height dimensions 10. High approach and return speeds for production bending. Approved in AHYW-Anhui Yawei Company Overview AHYW-Anhui Yawei Company Overview New Shop Building in AHYW-Anhui Yawei Modernly Management in AHYW-Anhui Yawei Modernly Managent in AHYW-Anhui Yaw Packaging & Shipping Packing and Shipping Heavy Duty Machinery Loading Container in Gauge for Exportation Loading FLAT RACK Container Loading Service & Contacts Service and Contacts AHYW-Anhui Yawei welcome you attend our Annual Training Course for further cooperation. Map on Site Manufacturer Anhui Yawei Machine Tool Manufacturing Co., Ltd. Address Pingqiao Industrial Park, Bowang, Maanshan City, Anhui Province, China Tel 0086-5 Website Contact Mr.

• E21S Operation Manual (Version: V1.05) • E21S Operation Manual Contents Preface..1 Chapter 1 Product Overview.. 2 1.1 Product introduction.2 1.2 Operation panel.. 2 1.3 Displayer..4 Chapter 2 Operation Instruction.5 2.1 Basic operation procedure.5 2.2 Programming..6 2.2.1 Single-step programming.. • Copy right is preserved by ESTUN.

It is not allowed to add or delete part or all of the manual content without ESTUN’s consent. Do not use part or all of manual content for the third party’s design. • E21S Operation Manual Chapter 1 Product Overview 1.1 Product introduction This product is equipped with the shear machine dedicated numerical control device which is applicable to various users.

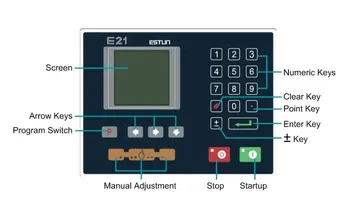

Based on ensuring work precision, the cost of numerical control shearing machine is reduced significantly. • E21S Operation Manual Functions of panel keys are described in Table 1-1.

Table 1-1 Description of key functions Function description Delete key: delete all data in input area on left bottom of displayer. Enter key: confirm the input content. If no content is input, the key.

• E21S Operation Manual 1.3 Displayer E21S numerical control device adopts 160*160 dot matrix LCD displayer. The display area is shown in Figure 1-2.

Single Title bar 200.00 50.00 9.98 20.00 Parameter display area CUT: 3.00 DLY: 1.00 Range: 0~9999.999mm Status bar Figure 1-2 Display area . • E21S Operation Manual Chapter 2 Operation Instruction 2.1 Basic operation procedure Basic switch over and operation procedure of the device is shown in Figure 2-1. START Press Press Manual Single-Step Press Press Press Mutil-Step PROGRAMS Press Press Press Password: 14789.

• E21S Operation Manual 2.2 Programming The device has two programming methods, which are single-step programming and multi-step programming. User can set up programming according to actual demand. 2.2.1 Single-step programming Single-step programming is generally used for processing single step to finish work piece processing. • E21S Operation Manual Parameter name Unit Range Remarks 0~9.99 In case of single step, delay time for X axle concession. 0~9.99 There is a delay time for the cutter goes to the next work-step, after it leaves the top dead center. • E21S Operation Manual Operation steps Operation Step 4 Click, select “DX” parameter, “DLY” parameter, “PP” parameter respectively.

Step 5 Set up parameter to 50mm, 2s, 10 by numerical key. Step 6 Click, system execute according to this program. • E21S Operation Manual Step 5 Click, select multi-step programming parameter which requires set up, input setting up value, click, and the configuration takes effect. Step 6 In completion of set up, click, enter step parameter set page, as shown in Figure 2-6. • E21S Operation Manual Parameter name Unit Range Remarks CtDly 0~9.99 There is a delay time for the cutter goes to the next work-step, after it leaves the top dead center. [Note] Only the parameter CutDelay En.

Geometriia: zadachi na gotovykh chertezhakh: 8 klass (Russian) Paperback – 2017 by Balaian Eduard Nikolaevich (Author). Zadachi po geometrii na gotovih chertezhah 8 klass.

Is set to 1, displaying this parameter. • E21S Operation Manual Table 2-4 Operation steps of multi-step programming example Operation step Operation Step 1 On single step parameter setting page, press to enter program selection page. Step 2 Input “2”, click, enter multi-step general parameter setting page of program 2. • E21S Operation Manual Step 1 On program management page, click to enter programming constant page, as shown in Figure 2-8.

- четверг 20 декабря

- 16